About Us

The Geomat is a wastewater recovery system that can be used for a variety of applications. The system is ideal for both semi-permanent and permanent facilities and can be built to any specification. It elevates workers above the water on an OSHA-approved non-skid work surface allowing water to runoff and be pumped into an optional holding tank or sanitary sewer system. Made from state-of-the-art materials, the Geomat will withstand even the strongest chemicals. The system allows for maximum water efficiency, maximum water quality, and a minimal impact on the environment. To meet water quality regulations, toxins and contaminants need to be prevented from entering the environment and Geomat does just that.

The goal is to provide businesses with a sustainable, cost effective, and EPA and OSHA approved solution to the issues of water quality and water scarcity. Geomat has experience in the following industries:

Geomat is involved in the cannabis/produce industry. The technology is ideal for

commercial cannabis grow facilities who want a water containment solution that can be quickly installed, with minimal disruption to production. A Geomat a offers durable and high-quality water containment system to help growers scale operations and ensure that environmental regulations are met.

Geomat is involved in the auto industry, providing products to car wash and car rental locations throughout the U.S. and Canada. The runoff from washing cars contains chemicals that can end up in surface waters or infiltrate into ground water, wells, or septic systems. The car wash closed loop system is proven to be an effective cost reduction tool for the auto washing industry as well as minimizing their environmental impact.

Geomat has a long history of working in the hazardous material and decontamination field.

To meet hazmat containment needs, Geomat designs environmentally friendly systems of all scale sizes for local, state, and federal agencies. Partners include, but are not limited to, the NYC Fire Department, FBI First Response Team, and St. Pete Fire Department.

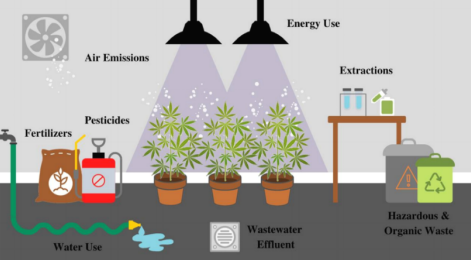

The Cannabis Industry

As the cannabis industry expands, businesses are constantly seeking out the newest and most efficient ways to grow. With water being the most intensively used resource in the cannabis industry, it is important for many reasons that it is used in ways that are most efficient and environmentally cautious. Not only is water quality an issue, but water availability is an issue as well. Water scarcity has become a problem in recent years and with the market for cannabis growing at an annual rate of 18%, these issues will only get worse without proper policies and regulations on water use in the industry (New Frontier Data, 2021). Depending on watering techniques, 25% or more of water applied for irrigation of cannabis plants runs off into the drain. When applying water using a hose, half of the water often does not even reach the pot (New Frontier Data, 2021). Improper watering techniques lead to the waste of potable water as well as chemical runoff contaminating the environment. For these reasons, it is crucial to maximize water efficiency by implementing systems to filter and recycle water.

A Geomat is a water containment system that pumps wastewater into a holding tank where it is filtered and pumped back for further use. This system saves water, money, and has minimal impact on the environment. Although cannabis is not considered the thirstiest of plants, water is still used in abundance throughout facilities and farms. Irrigation and cleaning is where water is used the most within the industry and with the irrigation technology, not much water is wasted when watering the flower. On the other hand, hundreds of thousands of gallons are used each year to wash and sanitize the trays and tables that the flower is grown on. The majority of that water goes into the drain, into the sewers, or out into the environment due to runoff. With Geomat, that water can be filtered and reused a number of times resulting in reduced water use, reduced costs, and reduced impact on the environment.

Water Scarcity

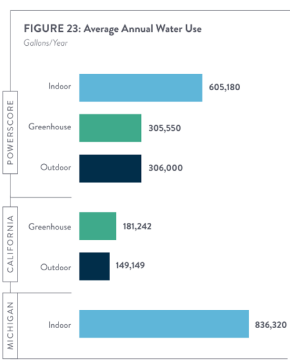

Water is a scarce resource and should be used efficiently throughout all industries, including the cannabis industry. With the amount of water that is needed for any type of farms to be successful it is important that farms have a system in place to limit water usage in effort to be as sustainable as possible from irrigation to cleaning, Cannabis cultivation facilities use water in eight different ways; irrigation, storage, applying nutrients or other substances to the plants, humidification, cooling, cleaning, pest control, and non-cultivation (New Frontier Data, 2021). Irrigation and cleaning are two of the most intensive uses. The figure below captures data from cannabis facilities in California, Michigan, and facilities using the free Power Score benchmarking tool used to help cultivators track and understand their water and energy usage. Indoor facilities are averaging over 600,000 gallons of water per year according to Power Score. Water is a necessity to feed and maintenance these plants, it is not different from produce or other mass-produced crops. But cultivators can be smarter with their water use for the sake of water scarcity issues and utility costs.

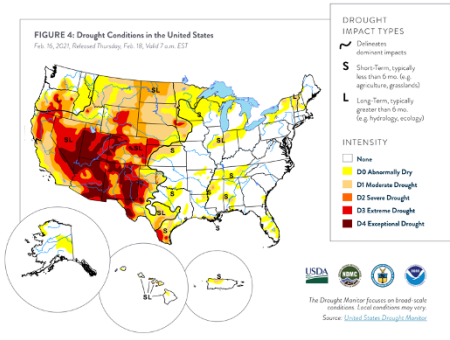

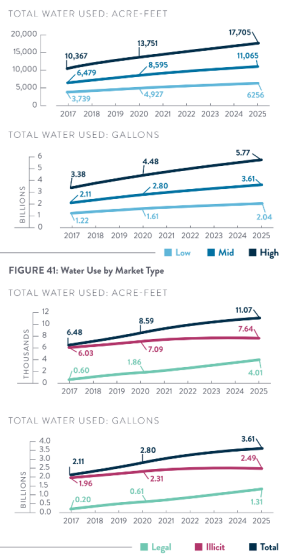

As time goes on, new facilities will have premium water use technology and existing facilities will have to adapt. It is ideal for facilities to get ahead of the pack and start practicing sustainable water usage as soon as possible. There is not enough water in the world to keep using water in the irresponsible ways it has been used. Major cannabis markets in the Western U.S. such as Arizona, California, and Colorado are currently experiencing severe drought conditions and water shortages (New Frontier Data, 2021). With a future containing high water demand and low water supply, this is an issue that can seriously effect industries such as the cannabis industry. These drought conditions can be seen in the figure below.

Cannabis facilities need to take advantage of water reuse techniques. Researchers estimate total water usage in the legal industry will increase by 86% by 2025 (New Frontier Data, 2021). Sustainable technologies and practices such as wastewater treatment systems, drip irrigation, and rainwater harvesting can aid the movement for more efficient water usage. It has never been more important to improve water efficiency in the world, let alone the cannabis industry.

Water Quality Policies and Regulations

The industry’s practice needs to focus on minimizing water usage and eliminating impacts to water quality from discharges into the environment (NCIA Environmental Committee, 2020). As of now, there are not any federal policies or regulations on water quality in the cannabis industry due to the fact that cannabis is not legal at the federal level. The Federal Insecticide, Fungicide, and Rodenticide Act (FIFRA) requires that all pesticides sold and distributed in the U.S. be registered by the Environmental Protection Agency. Because cannabis is not legal under federal law, the EPA has not regulated pesticides within the cannabis industry or even investigated it for that matter (Salerno & Jacquelyn, 2020). With cannabis only being legal in some states, no states have the same laws and policies which can lead to inconsistencies between states. For example, some states have an agency dedicated to the cannabis industry such as the Massachusetts’ Cannabis Control Commission, while other states choose to regulate through already established departments or agencies (Salerno & Jacquelyn, 2020). With inconsistency and the variation of policy between states, there has been little to no environmental policy regarding cannabis. No states with legal recreational cannabis have any regulations towards specific cannabis pollutants (Salerno & Jacquelyn, 2020). At this point, governments and regulators have opportunities to collect data in the benchmarking process to support the industry’s future growth while offering improvements. These findings will eventually lead to more specific state and federal policies. An example of one of California’s policies is the California Cannabis Cultivation Policy, which “creates a strict set of rules cannabis cultivators will need to follow in order to protect water quality and quantity.” The policy was developed in consultation with the California fish and wildlife department and the California food and agriculture department. It has been incorporated into all commercial cannabis licenses issued by CDFA under its CalCannabis Cultivation Licensing Program (3C Cannabis Consulting, 2018).

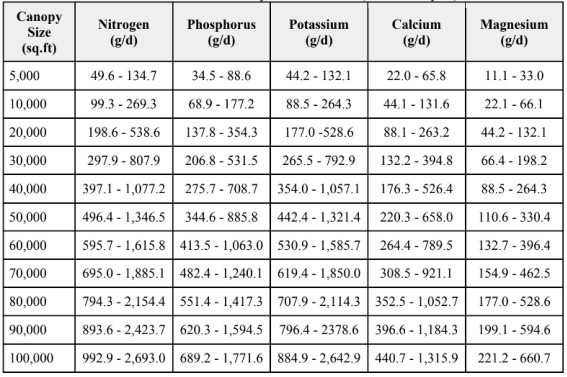

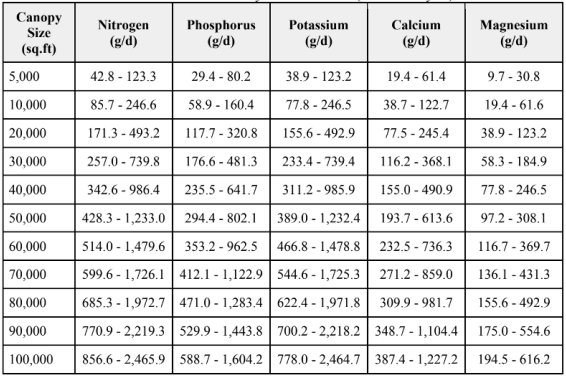

As the industry continues to grow, policies such as the Cannabis Cultivation Policy will become more abundant throughout the states and Canada, and eventually become federal regulations. Regulators may consider requiring licensed growers to report their water use, as some states have already done, to gather more data on water in cultivation (New Frontier Data, 2021). Recording water use will promote efficiency and create incentive for less efficient farms to improve their performance. As statistics show the inefficiency within the cannabis industry, growers will develop water efficiency solutions to save water, money, and mitigate impact on the environment. Irrigated agriculture in the United States accounts for an estimated 80% of water use nationwide (NCIA Environmental Committee, 2020) and agriculture is one of the largest sources of water pollution, effecting water quality due to runoff contaminated with pesticides and fertilizers. The production of cannabis can cause these same issues and will require federal regulation as well as state and local regulation for specifics. Both indoor and outdoor cultivation facilities have runoff concerns and are in need of a containment or filtration system to meet policies and regulations. Water in the cannabis industry is invaluable and as time goes on more polices and regulations will be put into place, which requires cultivation facilities to meet specific standards relevant to the area they are located. Water filtration systems will be needed to meet these standards as they continue to get more intense in the future. The below charts show potential cannabis pollutants and the amount in which they can runoff into the environment.

Outdoor Facility Nutrient Runoff

(1 Harvest Cycle)

Indoor Facility Nutrient Runoff

(1 Harvest Cycle)

Why Geomat?

Geomat is ideal for commercial cannabis grow facilities who want a water containment solution that can be quickly installed with minimal disruption to production. Illegal and legal cannabis cultivation is estimated to use about 2.8 billion gallons of water a year and with the industry and the population growing, this number will only increase (New Frontier Data, 2021). Geomat helps reduce this number by recycling wastewater for further use. The systems offer a durable and high-quality water containment solution to help growers scale operations and ensure that environmental regulations are met. Like all produce and crops, cannabis contaminates water runoff with fertilizers, THC, and other chemicals from cleaning. The Geomat system, depending on the installation, filters the chemicals out of the wastewater and allows for either a release into the sewers or to be pumped back for future use.

The easily adaptable systems are backed by a 10-year warranty and can be quickly installed ensuring minimal disruption to production. It is a state-of- the-art system made from high- qualitycomponents, allowing grow facilities to produce and maintain high product quality. Geomat allows facilities to reduce, reuse, and repeat. When it comes to water usage, businesses can be confident that their facility meets all Clean Water Act and EPA requirements. The Geomat also promotes grow facility safety by avoiding unnecessary floor water damage and reducing the risk of employees falling with a non-skid work surface.

Some companies turn to reverse osmosis to solve their water use issues. Reverse osmosis is an alternative way of recycling wastewater, but it creates a byproduct that still requires disposal. For every five gallons of water treated with reverse osmosis, four gallons of waste is produced (Ganjapreneur, 2021). The reverse osmosis process not only creates a waste byproduct, but it is also very energy intensive, requiring a lot of electrify, offsetting efforts to reduce energy use in the cannabis industry (New Frontier Data, 2021). Geomat does not use reverse osmosis and therefore does not create a waste by product or require an abundance of energy. Instead, Geomat has its own, unique filtration system that offers two options for cultivation clients to reuse water on-site. One being a system that can go back into municipalities to be treated by city water systems, and one with an on-site, closed loop treatment plan.

Geomat Products

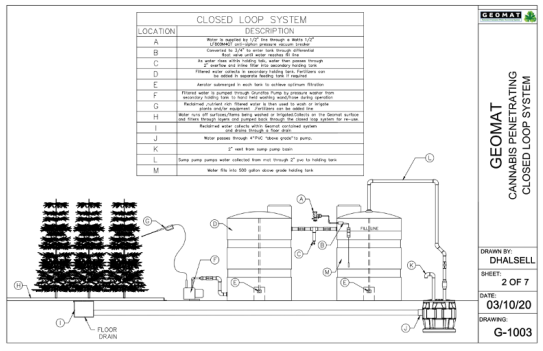

Closed Loop System

The closed-loop water recovery system recycles and captures all water used in washing of equipment and plants, which maintains nutrients and saves on water usage and cost.

The installation is minimally disruptive and leaves no environmental footprint. Not only does the closed loop system reduce water usage and cost, but combats any mites, pests, mold, and residue that may linger from plants and equipment.

Excess water used to irrigate or clean falls through the Geomat and goes through a filtration and decontamination process, eventually leading back to a holding tank where it is reused for further use.

This product is backed by a 10-year warranty and allows facilities to meet all Clean Water Act and EPA requirements.

The closed loop system promotes maximum water efficiency with minimal impact on the environment.

The figure on the bottom is an image of a tray being cleaned on a Geomat installed at a major cannabis facility in Central Florida.

Geomat Products

Closed Loop System

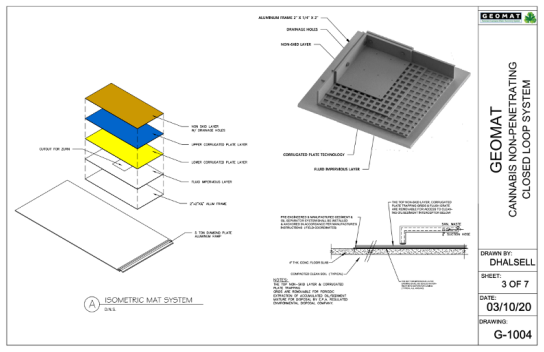

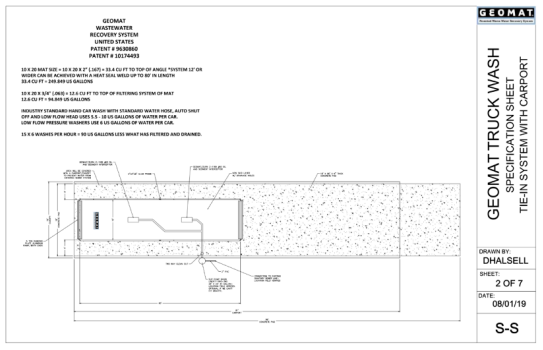

The sewer connected system is an effective tool in reducing costs and environmental impact across range of industries. It is a patented system with low maintenance and high durability and is intentionally designed with a slope drain in order to provide optimum filtration and wastewater containment.

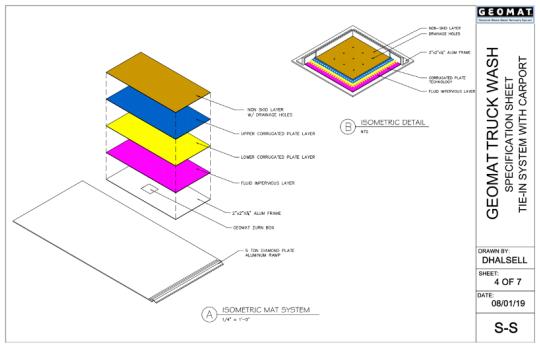

Water flows down through the filtration grid and is contained by an oil impervious membrane which is attached to a 2” x 2” aluminum perimeter frame.

The wastewater is disposed of and manifested according to local and federal EPA guidelines.

Requirements for the Sewer Tie-In

System:

1. A level surface

2. A sanitary sewer line to connect to

A Geomat leaves no environmental or

construction footprint upon removal. It

can be relocated and installed

elsewhere if desired.

Penetrating And Non-Penetrating Systems

Both the closed loop system and the sewer tie-in system can be either surface penetrating or non-surface penetrating.

A penetrating system is built into the ground and delivers water to either holding tanks (closed loop system) or into the sewers (sewer tie-in) through underground pipes.

A non-penetrating system is an above ground system that delivers water to either holding tanks (closed loop system) or into the sewers (sewer tie- in) through above ground pipes.

Case Study

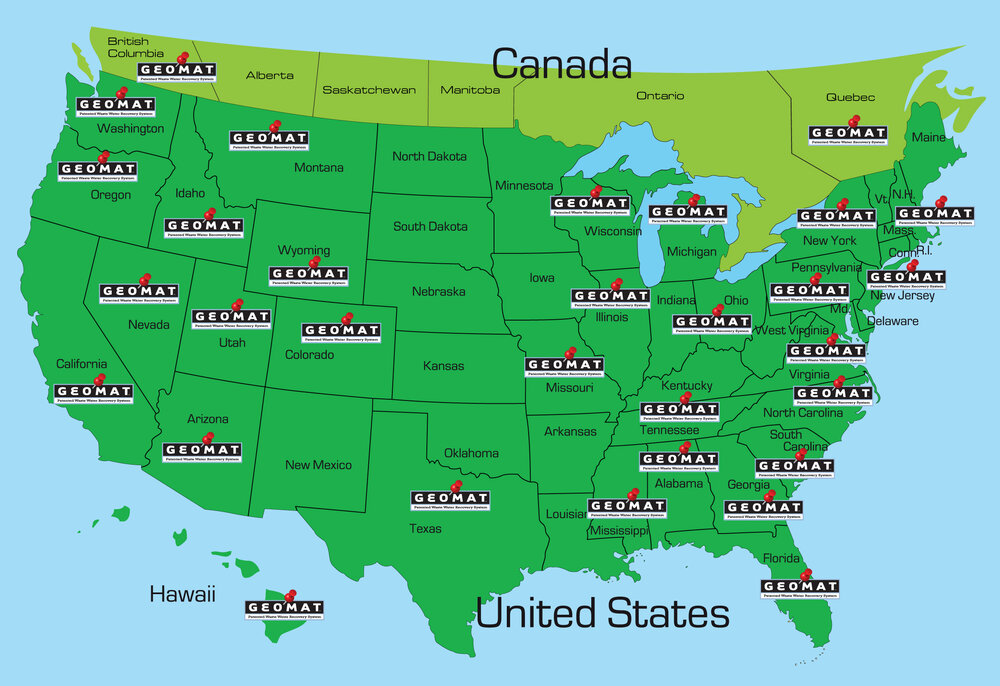

Our Locations

Our work speaks for itself. View our partial location and valued clients list below.

And Many More…

SERVICE AND MAINTENANCE

The patented Geomat system is designed to contain and increase the longevity of the water being used. Due to overspray while washing and water being carried off the wash area by the car / truck. The tanks may need minimal replenishing from time to time. This is done by connecting a standard flexible hose to the provided port.

Filters are visually inspected daily for sediment and can be easily removed and cleaned.

Upon determining the water is no longer suitable for washing, the tanks will be pumped and cleaned by a licensed hauler, disposed of and manifested according to local and federal EPA guidelines. The tanks will then be refilled and ready to be used again.

The patented Geomat filtering layers need to be cleaned annually (dependent on usage). This is done by a Geomat technician and all residual waste and sediment is disposed and manifested according to local and federal EPA guidelines.

GET A PERSONALIZED QUOTE FOR FREE

Address

P.O. Box 271852

Tampa, FL 33688